The art of a smoothly running warehouse is similar to a well-oiled machine: everything must work together in perfect harmony to achieve maximum efficiency. One of the crucial cogs in this machine is without a doubt the 'picking strategy'.

A good picking strategy can make the difference between a chaotic mess and a warehouse that is as efficient as a Swiss watch. If you use Odoo for your business operations, then you are in the right place because this software offers various picking strategies to take your warehouse management to the next level..

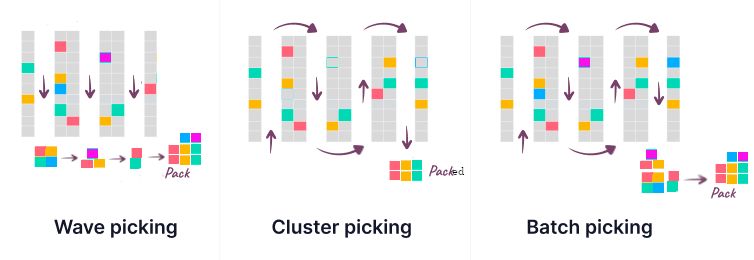

In this blog we dive into the three most important ones: batch picking, wave picking and cluster picking. We'll look at the pros and cons of each method and give you a comparison to help you make the best choice for your situation.

Wave Picking

What is it?

Wave picking is like a finely tuned orchestra. Employees collect items during specific 'waves' or time slots. The goal is to fulfill multiple orders in that time..

Advantages:

- Time Sensitive: Great for businesses where orders need to go out at specific times.

- Resource Allocation: Easier to allocate manpower and equipment if you know exactly when the pick-up will take place.

Disadvantages:

- Complexity: Requires good coordination and a watertight plan, otherwise it can lead to bottlenecks.

- Less Flexibility: The schedule may not allow for urgent, unplanned picks.

Cluster Picking

What is it?

With cluster picking, associates collect items for multiple orders into a single cart with designated areas for each order. This way, items for different orders can be picked up at the same time.

Advantages:

- High Accuracy: Lower risk of errors because you only focus on one cart.

- Versatility: Good for environments with a wide range of SKUs but lower quantities.

Disadvantages:

- Equipment needs: You may need specialized carts to separate items for different orders.

- Less efficient for large quantities: Not ideal if you need to collect large quantities of the same item.

Comparison

- Efficiency: Batch picking is generally the most efficient in terms of reducing labor costs, followed by wave picking and then cluster picking.

- Error rate: Cluster picking tends to have the lowest error rate due to its targeted approach, while batch picking can be riskier in this regard.

- Flexibility: Wave picking is the least flexible due to its dependence on timing, while batch and cluster picking offer more leeway.

- Equipment needs: Cluster picking often requires the most specialized equipment (think multi-bin carts), while batch and wave picking are less demanding in this area.

- Best for:

- Batch Picking: High volumes, similar items.

- Wave Picking: Time-sensitive, planned operations.

- Cluster Picking: Wide range of SKUs but lower quantities.

Batch Picking

What is it?

Batch picking is all about efficiency. Instead of picking one order at a time, associates pick items for multiple orders at once. This reduces the amount of travel time in the warehouse.

Advantages:

- Efficiency: Because you pick up multiple orders at the same time, you reduce repetitive actions.

- Lower labor costs: Fewer trips down the aisles means less time, which translates to lower labor costs.

Disadvantages:

- Errors: Picking up multiple orders can increase the chance of errors, especially if items are similar.

- Inventory Overhead: Larger batches may temporarily require more storage space, impacting inventory levels.

Choosing the right picking strategy often depends on the unique characteristics of your company. Each method has its strengths and weaknesses, and the best choice may depend on factors such as order volume, variety of items, and shipping schedules.

So if you want to optimize your warehouse operations, Odoo's flexible picking methods offer something for everyone. Adapting your picking strategy to your specific needs can significantly improve efficiency, reduce costs and increase customer satisfaction.

Odoo Orderpicking Strategies